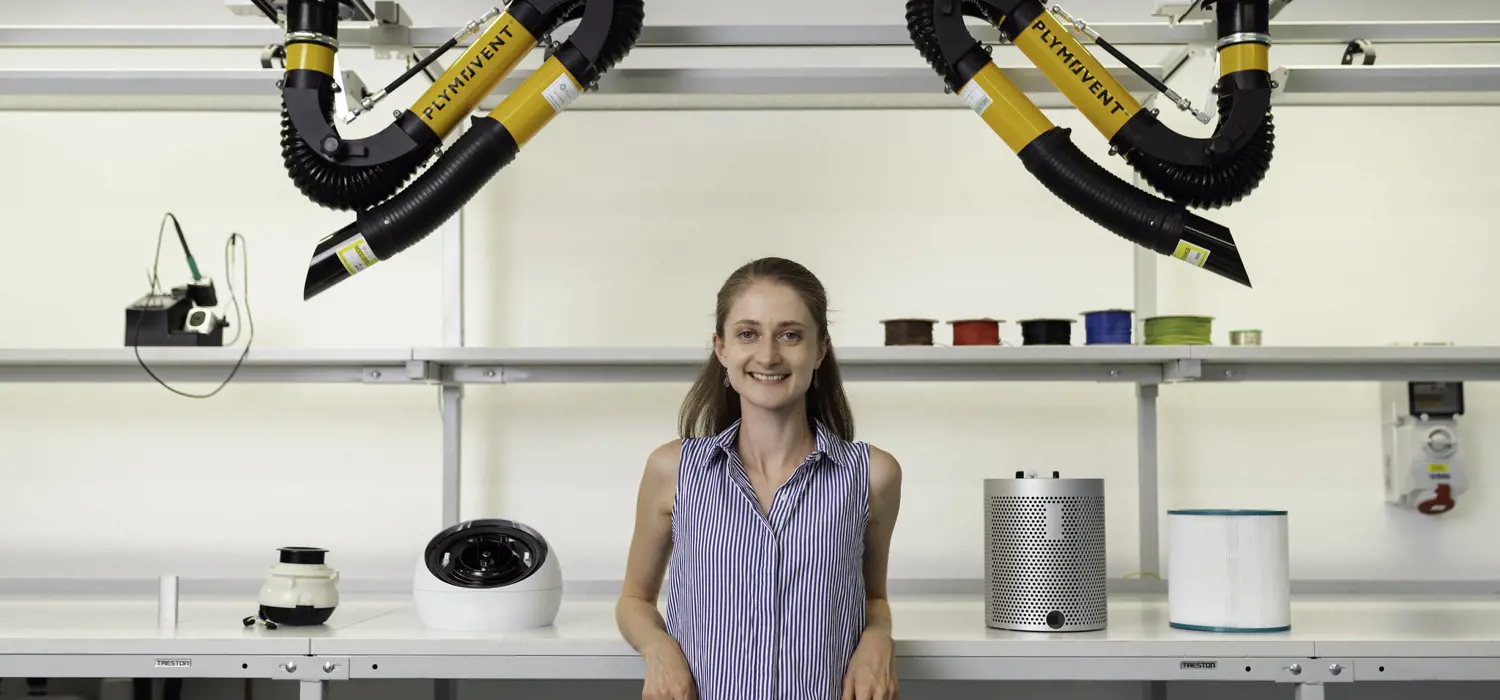

Lucy Richardson

Sound Sculptor

I’m from Cardiff and I love music and am fascinated by sound. I work for Dyson, developing products that are used in daily life. I am one of the acoustic engineers behind the Dyson Supersonic hairdryer and have helped invent quiet bladeless fans.

My current role

At Dyson, I am a Senior Noise and Vibration Engineer. Dyson makes many household products, from hairdryers and fans to the famous vacuum cleaner. These all need to work efficiently but can be noisy. My job is to design improvements and do experiments in the lab to make sure the products aren’t disruptive but stay high performing.

How I became an acoustics engineer

I grew up surrounded by science experiments and family projects to make and fix things from broken toys to pieces of furniture. I was also very creative. I danced, drew and loved music. When it came to choosing what to study, I considered everything from History of Art to Maths. I chose engineering as it let me be both creative and scientific. I studied Acoustical Engineering at the University of Southampton so I could use my passion for music and sound.

Before I went to university, I didn’t know how broad engineering could be and was surprised to be studying in the classroom one day and then welding in the lab the next. Now my job is a mix between working on the computer and being more hands on – I might be coding or pulling things apart.

Factfile

- Role

- Senior Noise and Vibration Engineer at Dyson

- Favourite part of engineering

- I love that I solve problems as part of a team, as well as working with engineering students

- Qualification path

- A levels, Acoustical Engineering at the University of Southampton

Day to day

My job means I get to travel and I have worked in Singapore and Malaysia. Working internationally means I get to meet new people and develop exciting solutions to everyday problems. There is also plenty of room for fun – I was once challenged to make a musical instrument out of Dyson parts and made a violin out of a Dyson Airblade hand dryer! I then performed with it on stage, mixing music, creativity and engineering together.

I love that I solve problems as part of a team, as well as working with engineering students, helping to train the next generation of engineers as part of their degree. It’s very rewarding when I go to a friend’s house and they show off their new quiet hairdryer or fan that I helped make.

"Before I went to university, I didn’t know how broad engineering could be"

— Lucy Richardson - acoustics engineer

Career timeline

A levels

University

Acoustical Engineering at the University of Southampton

Current role

Senior Noise and Vibration Engineer at Dyson

Think engineering could be for you?

Become an engineer